Home Sustainability Manufacturing & Certificate

In moving towards a greater degree of sustainability, Sunny Special focuses on every aspect of textile production where natural resources, energy, and chemicals are consumed and emitted to the environment.

We continue to make progress in energy efficiency and develop new technologies without using harmful materials. Our commitment to consumer safety and low environment impact has helped Sunny Special to be certified by Bluesign®, GRS, Higg, and Oeko-tex®.

Energy

Water

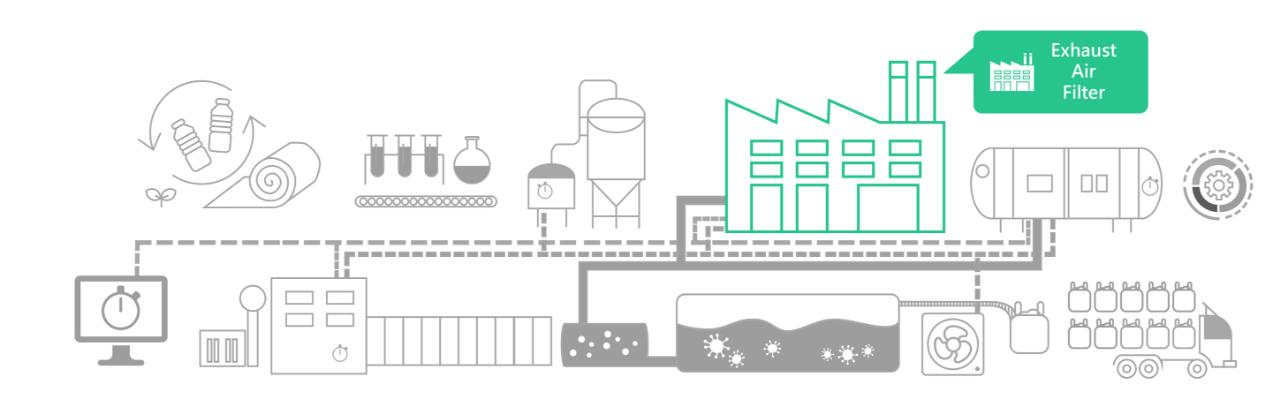

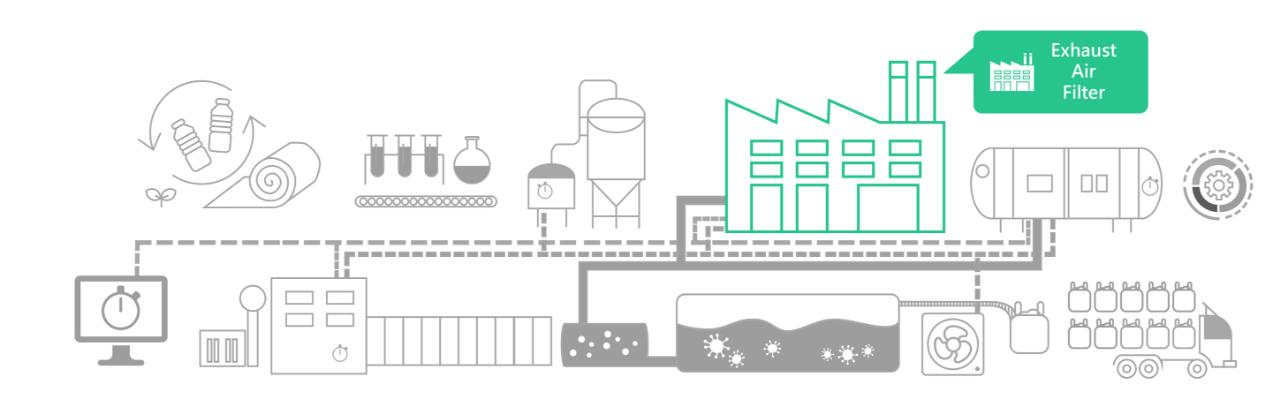

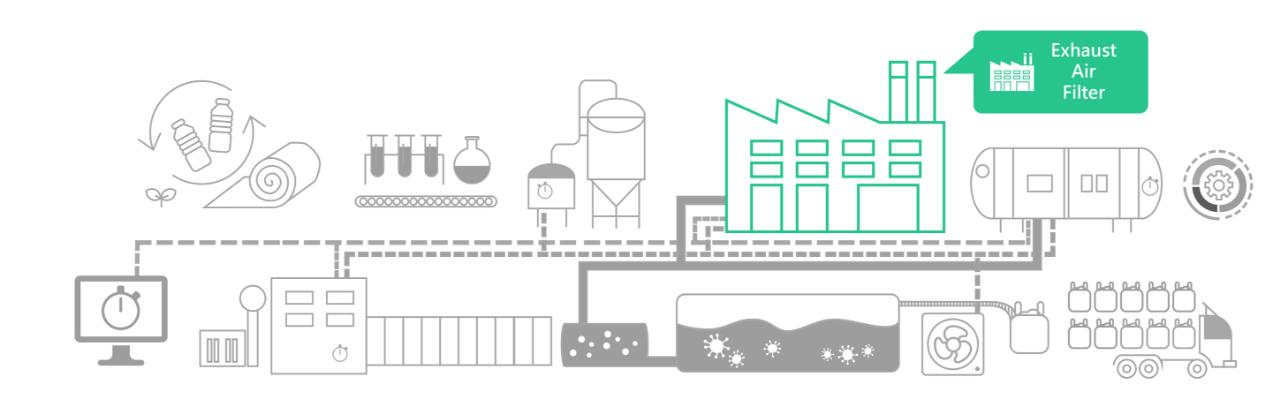

Air

Emission

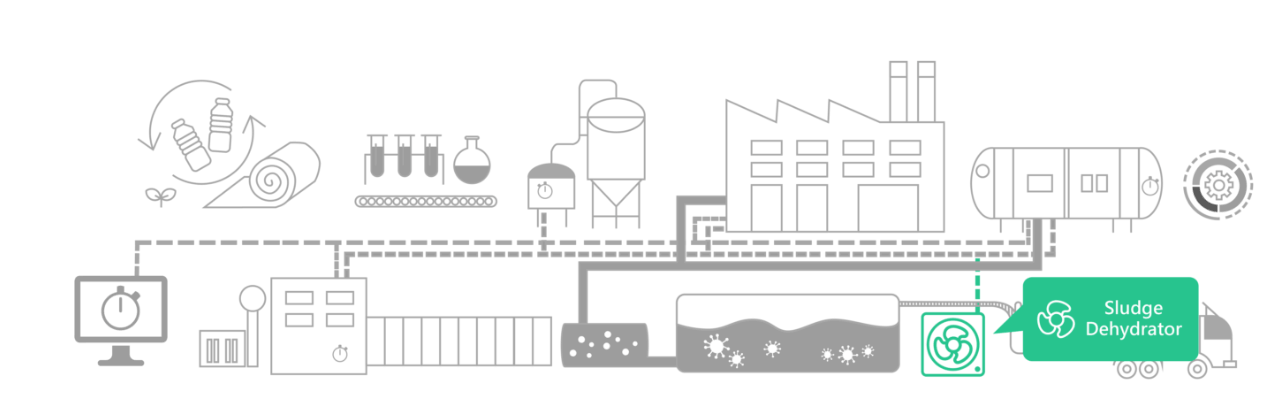

Waste

Material

Variable Frequency machine - 2020,2023

LED light - 2022

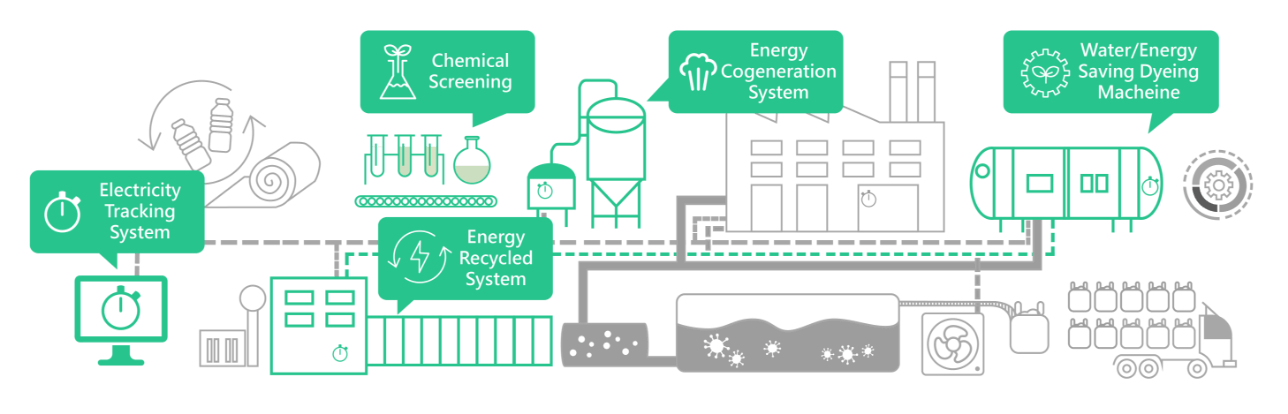

Energy cogeneration system - since 2018

Electricity tracking system - since 2015

Energy recycled sytem - since 2009

Energy saving machine - since 2008

Waste water reuse - since 2024

ZDHC clear stream - since 2023

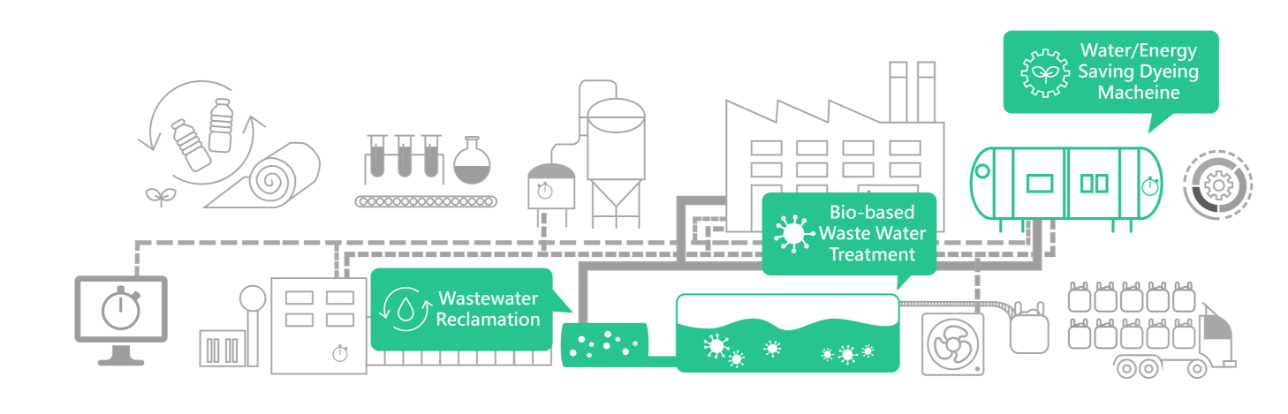

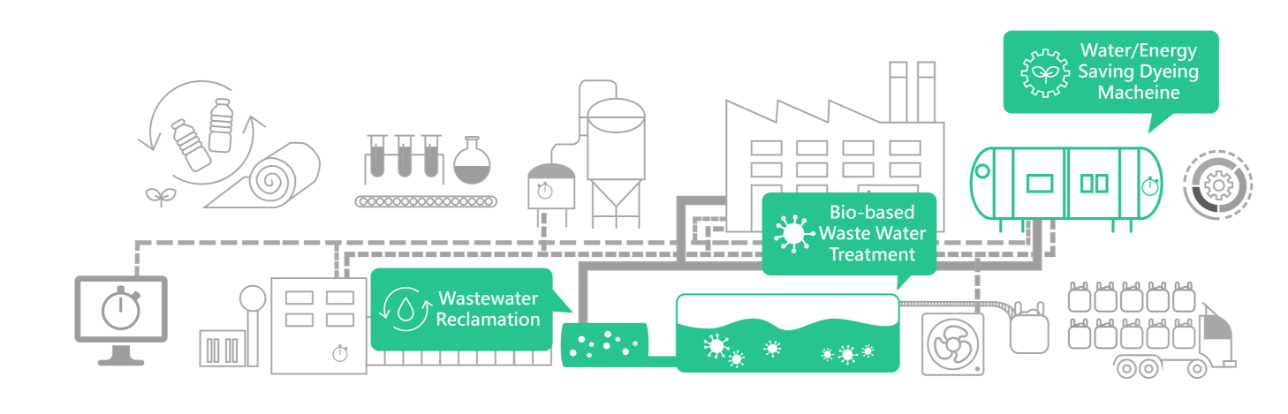

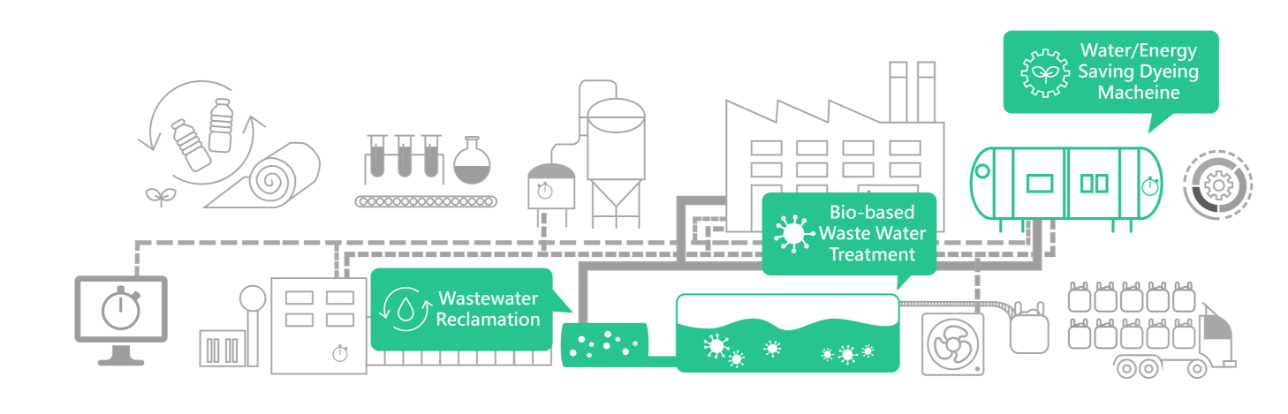

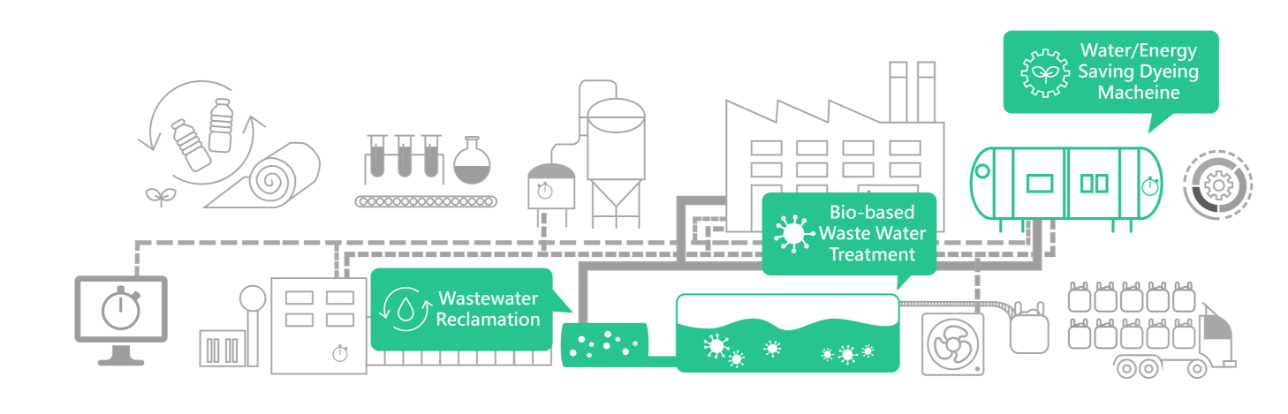

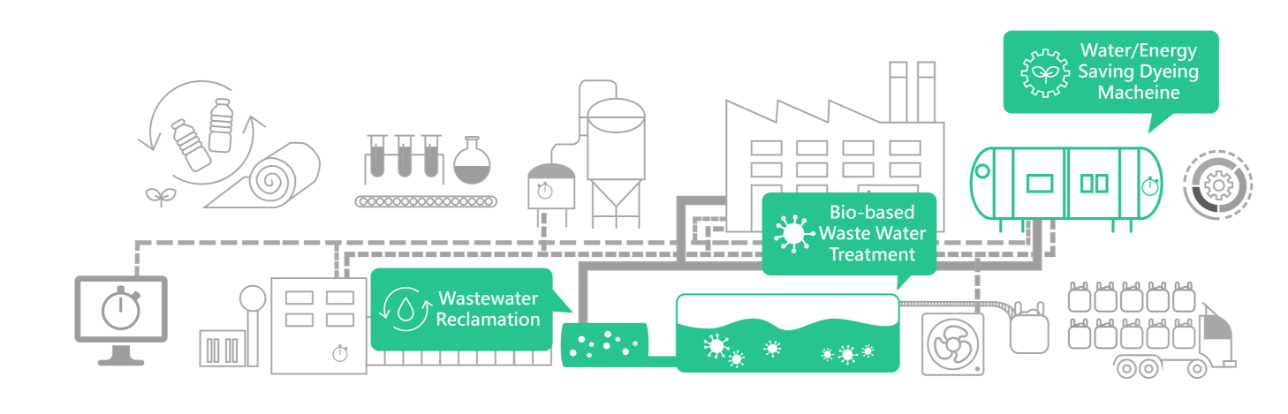

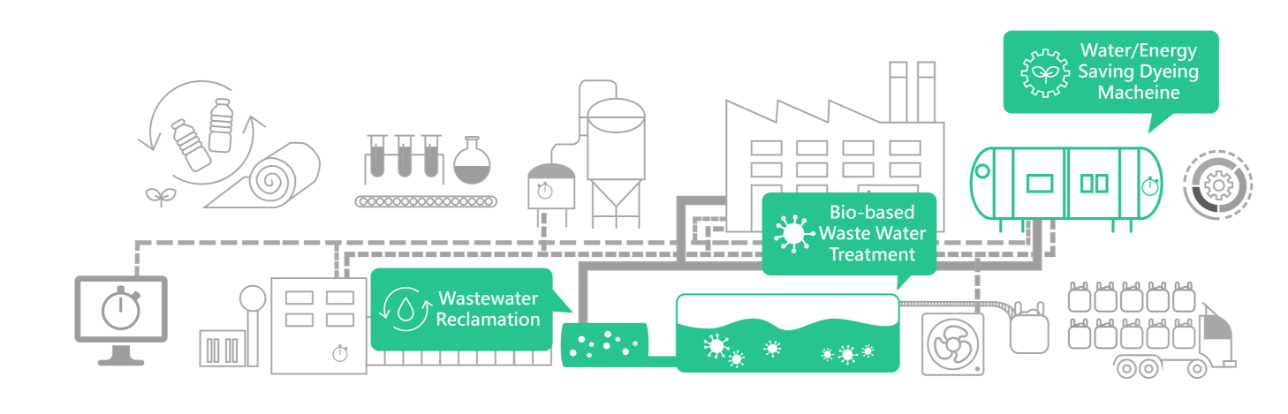

Waste water reclamation - since 2019

Bio-based waste water treatment - since 2011

Water saving machine - since 2008

Zero direct emission - since 2018

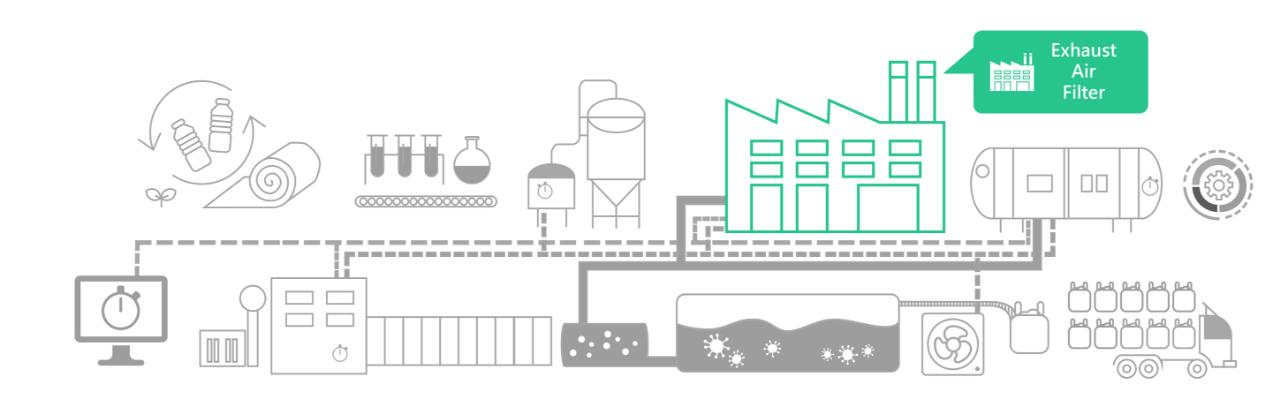

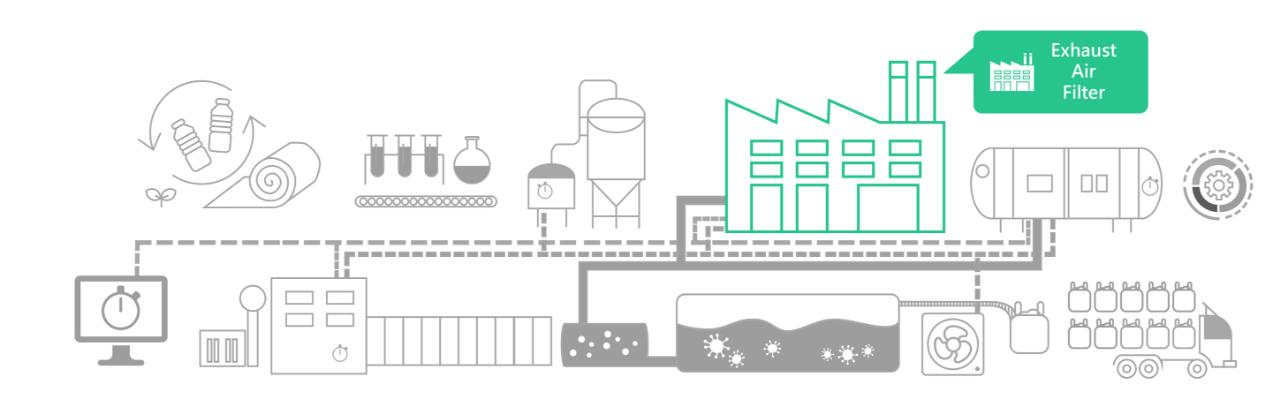

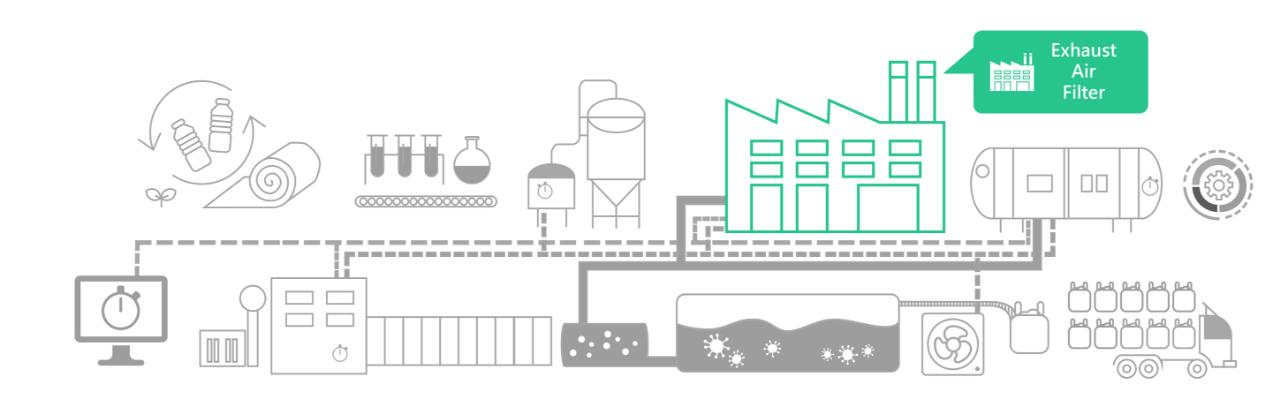

Exhaust air filter - since 2015

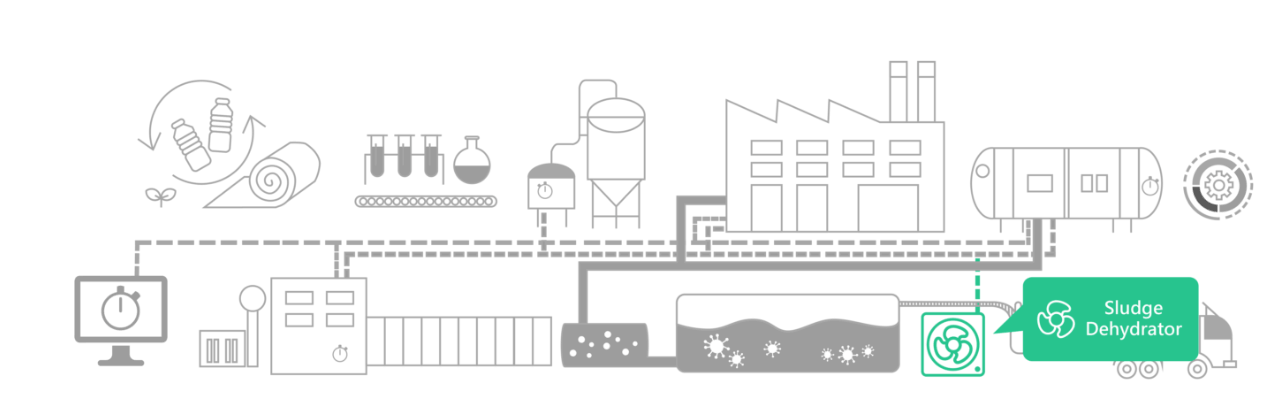

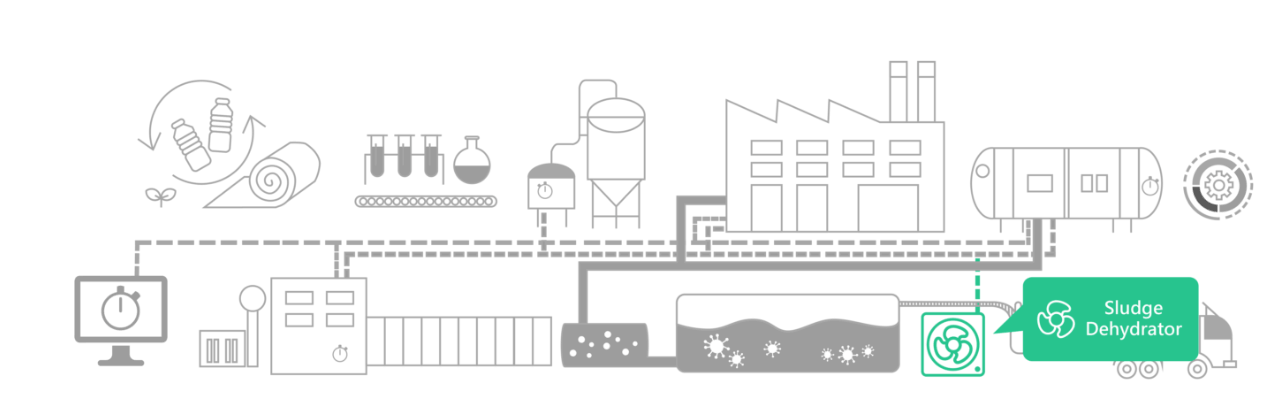

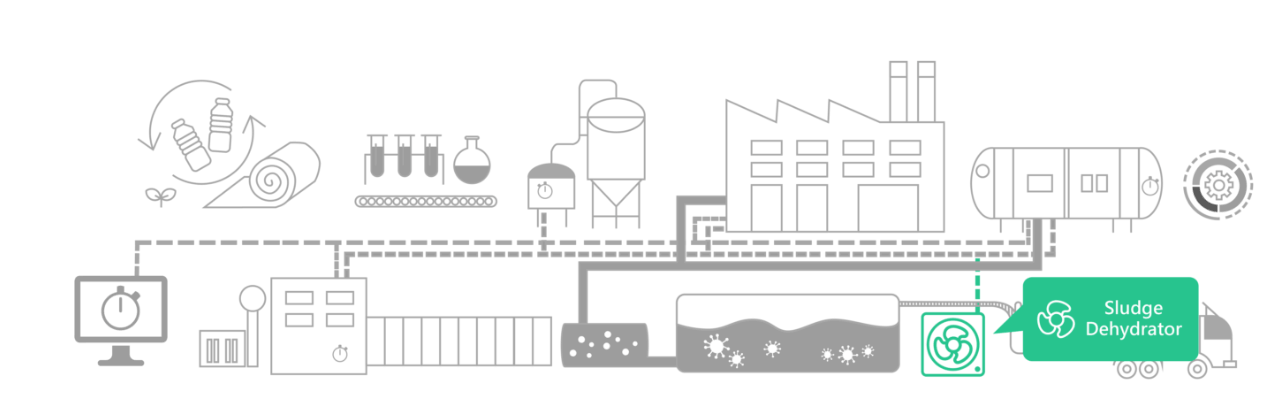

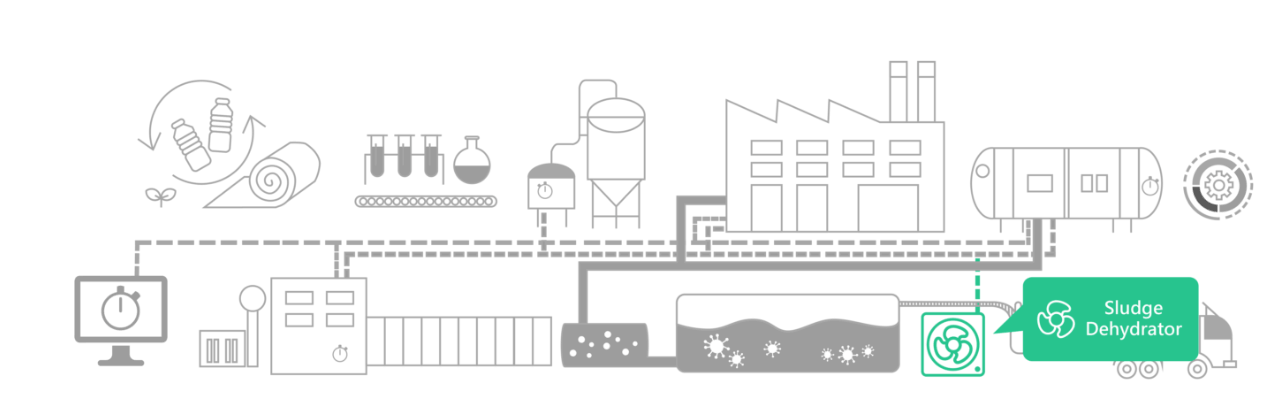

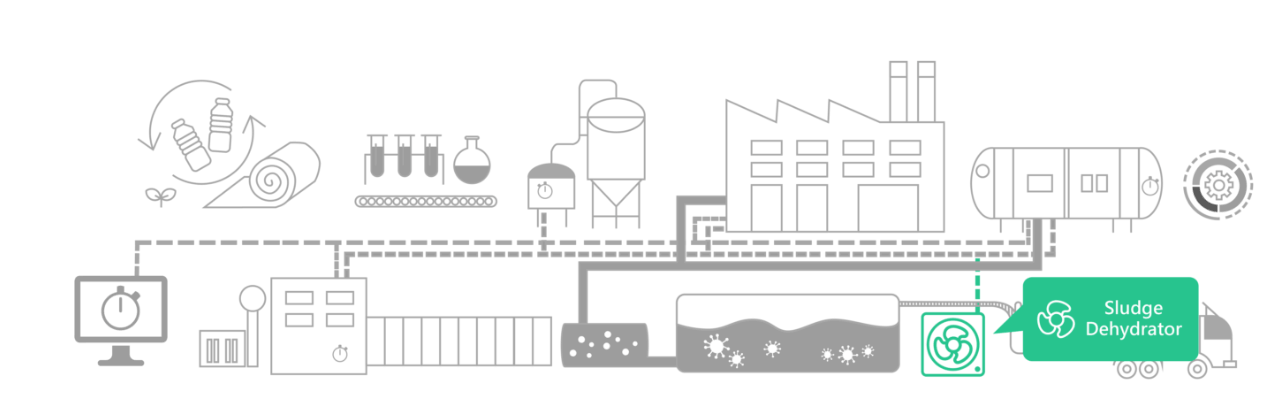

Sludge dehydrator - since 2016

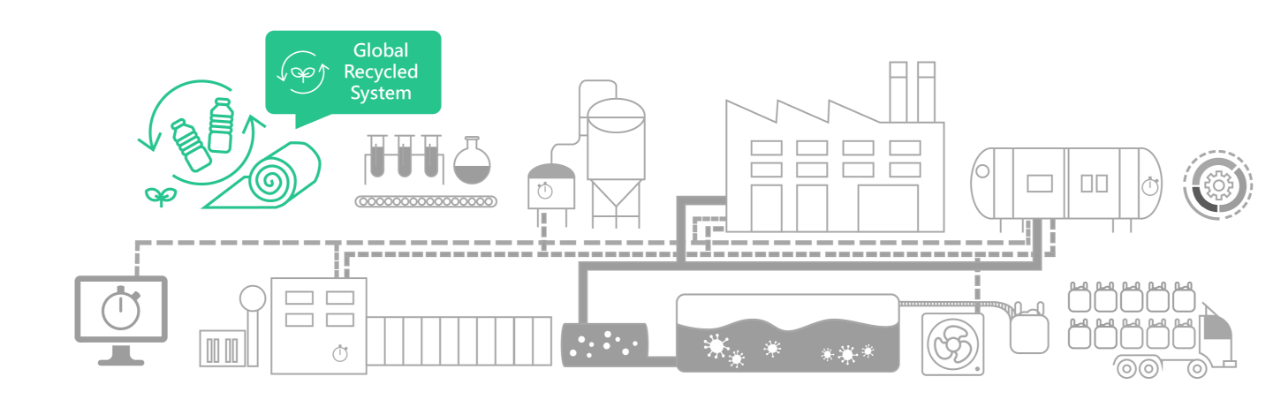

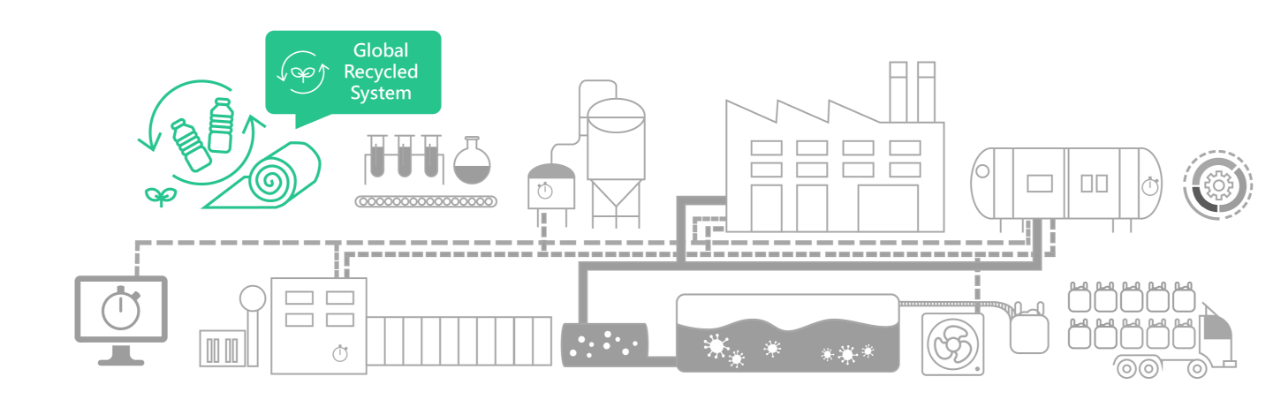

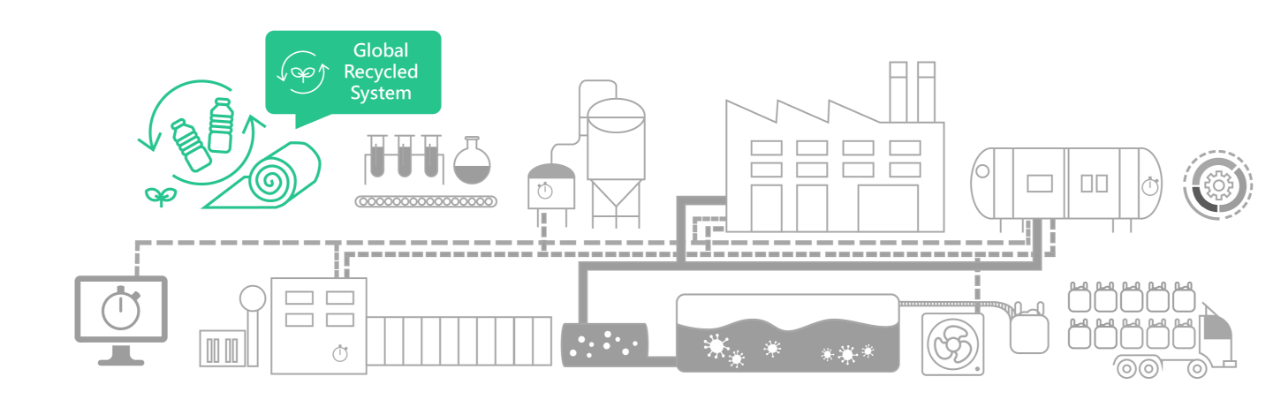

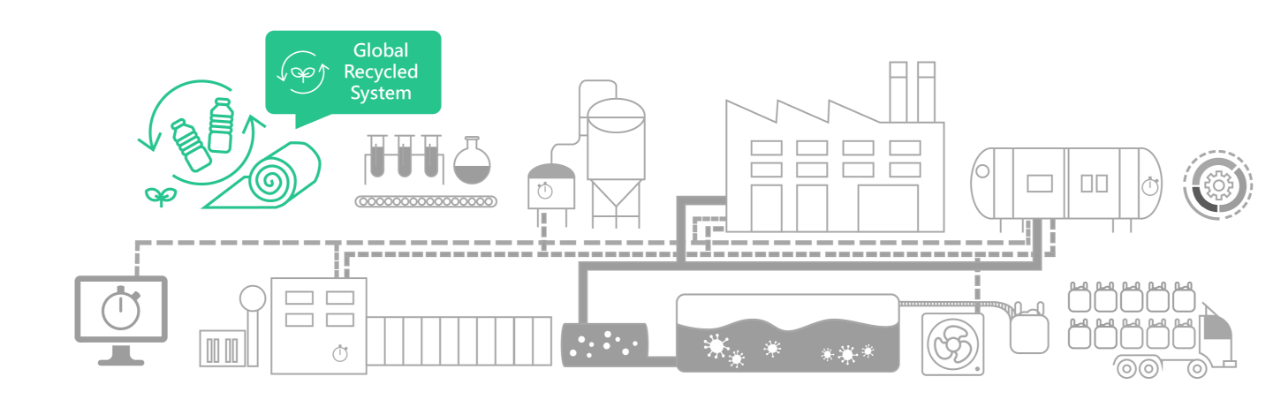

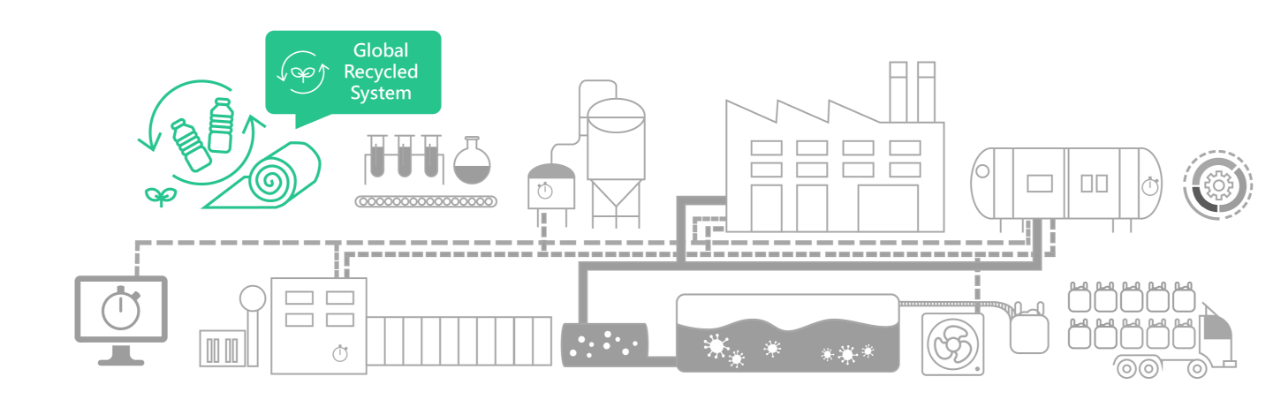

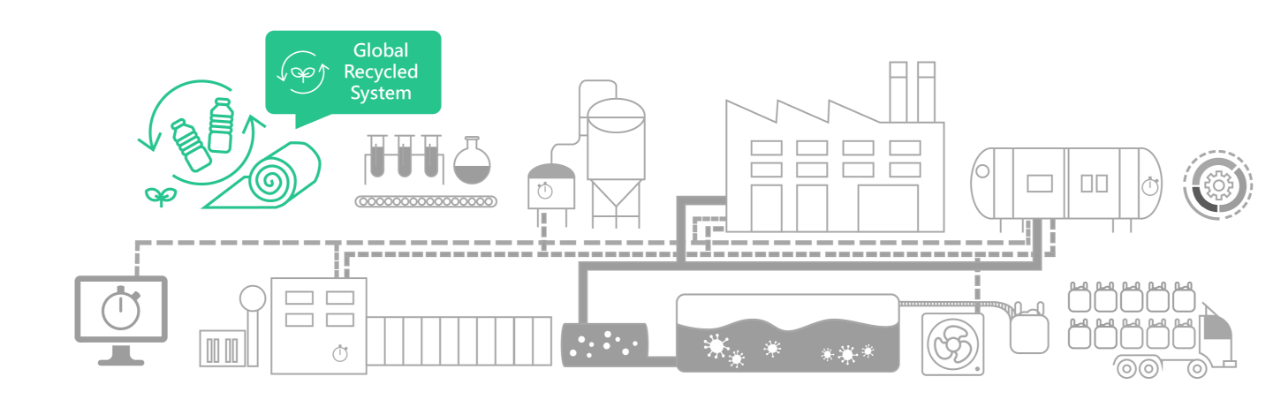

Fabric : GRS - since 2021

Chemical : bluesign - since 2008

Chemical : ZDHC incheck - since 2023

Variable Frequency machine - 2020,2023

LED light - 2022

Energy cogeneration system - since 2018

Electricity tracking system - since 2015

Energy recycled sytem - since 2009

Energy saving machine - since 2008

Waste water reuse - since 2024

ZDHC clear stream - since 2023

Waste water reclamation - since 2019

Bio-based waste water treatment - since 2011

Water saving machine - since 2008

Zero direct emission - since 2018

Exhaust air filter - since 2015

Sludge dehydrator - since 2016

Fabric : GRS - since 2021

Chemical : bluesign - since 2008

Chemical : ZDHC incheck - since 2023

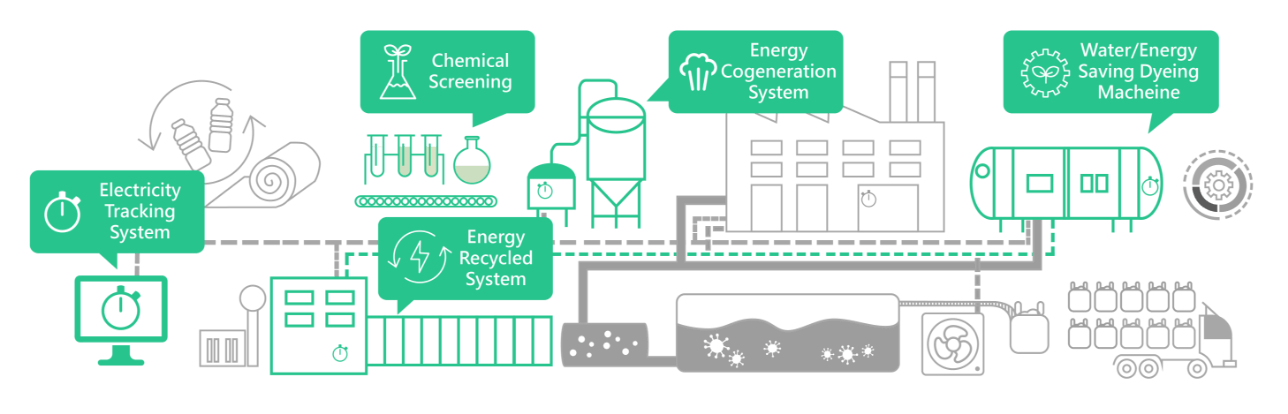

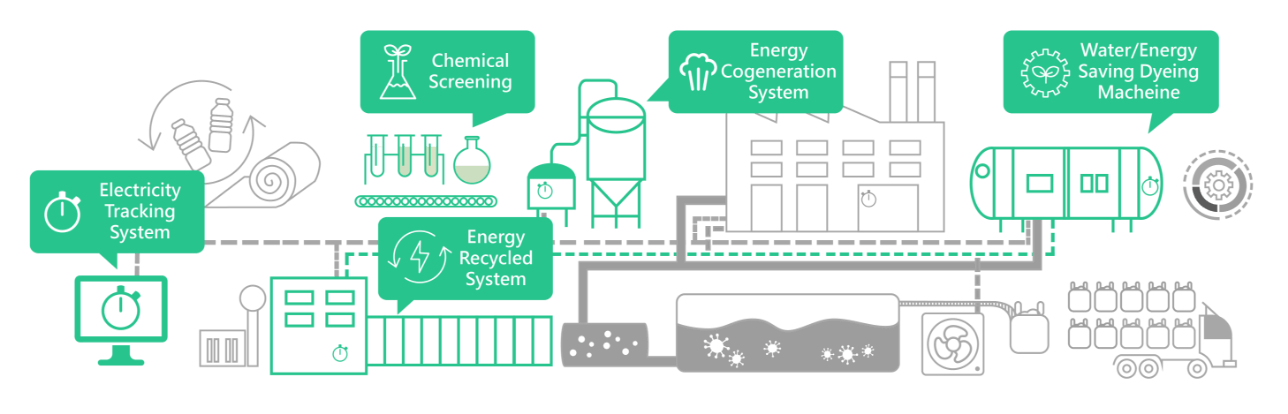

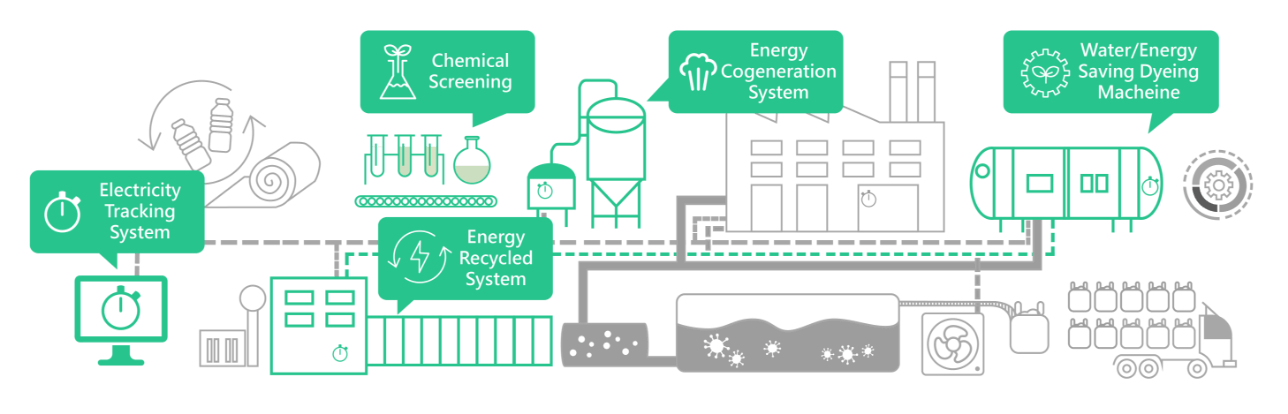

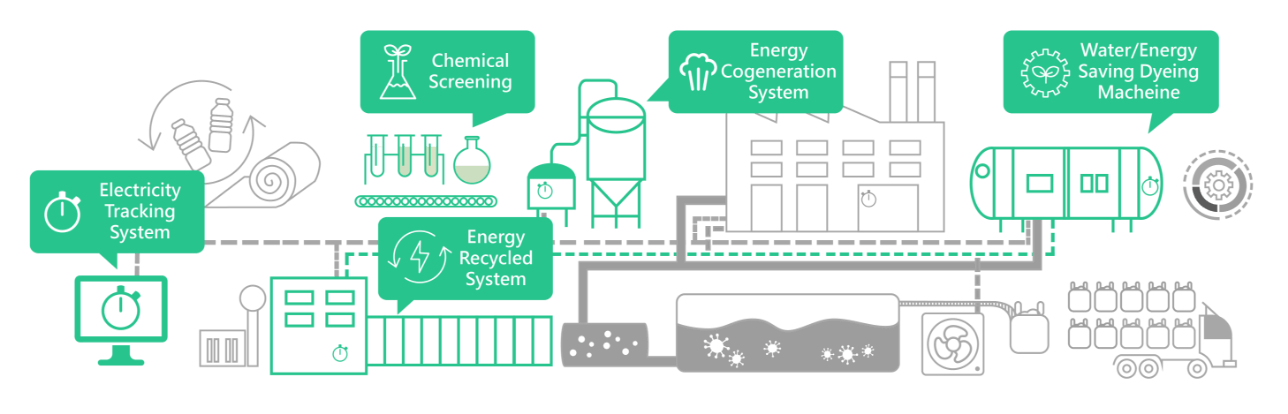

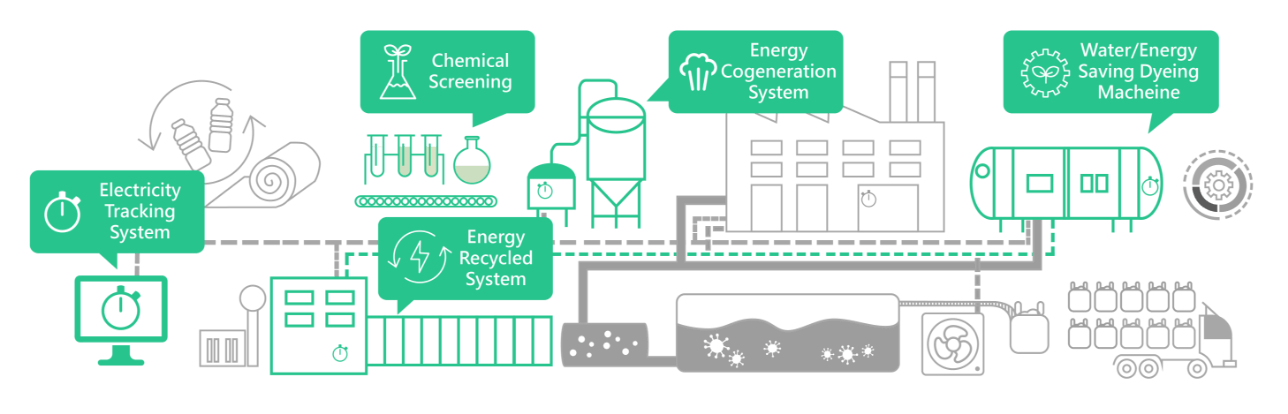

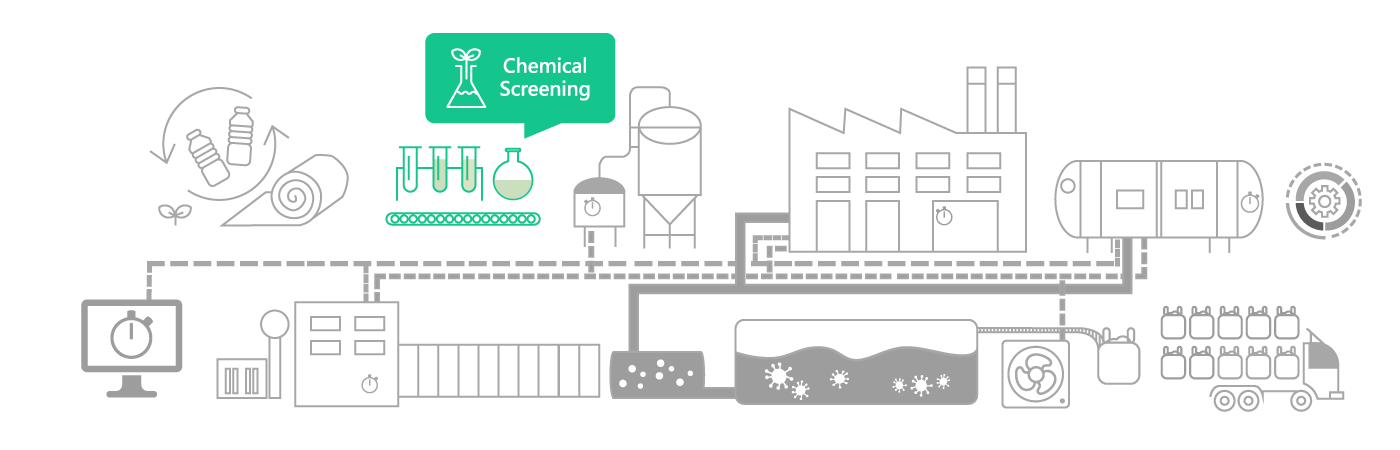

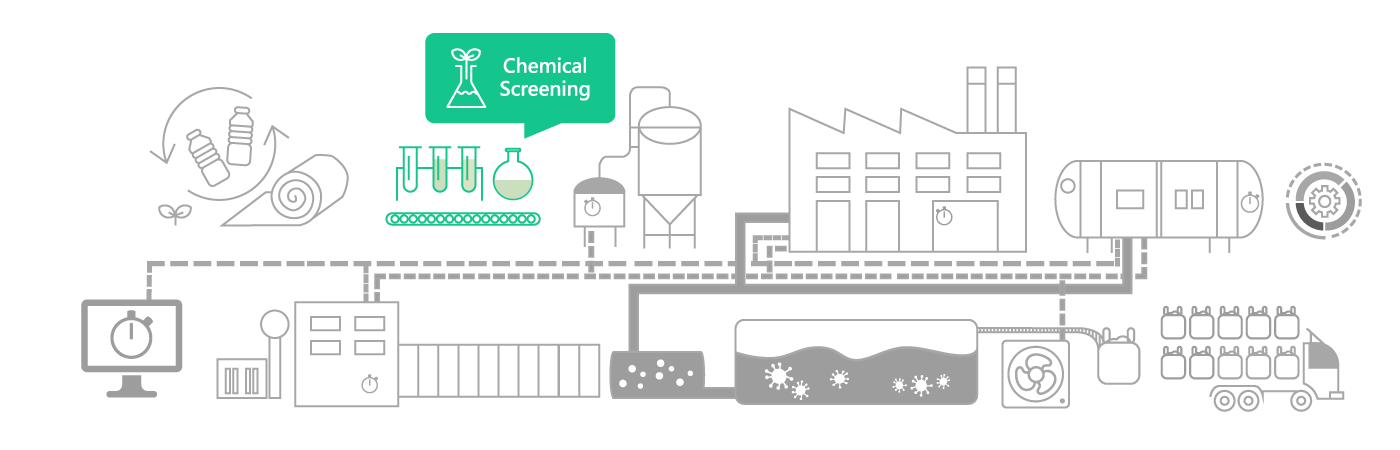

We maintain strict chemical screening to ensure the qualities of safe and non-toxic fabrics.

Regarding the water/energy saving dyeing machines, 30% of water is saved from the high-efficiency water-saving dyeing machine. Compared with a traditional dyeing machine, Sunny saved almost 50 liters of water per kg of textile by using the water-saving dyeing machine.

Most equipment is installed with a recycled energy system. The recycling path is arranged by temperature to ensure we make the most of energy without any waste.

In 2011, the Bio wastewater treatment system was renewed on site by adapting the latest biochemical technology, effectively dissolving contaminants in dyestuff with microorganisms. Our ultimate goal is to internally meet locally regulated domestic wastewater emission standards.

The company has an ISO 50001 energy management system installed with an electricity usage tracking/management system. The electricity consumption of all on-site machinery is tracked for future energy management purposes.

The off-gas filter exhaust heat generated from dyeing and finishing produces residual soot. Prior to omission, our newly installed off-gas filter system filters out volatile chemical gas and particulate pollutants through a washing and static cleansing process before safely exhausting pollutant-free gas into the atmosphere.

Sunny Special installed a sludge dehydrator using recycled heat to dry sludge, reducing the water content of sludge from 90% down to less than 40%, thus decreasing the volume of waste and enhancing cleaning efficiency, which benefits both the environment and the mill.

Sunny Special is leading cooperation with local gas and electricity cogeneration in Taiwan's textile industry by using a new generation of a circulating fluidized bed boiler steam generator set, saving fuel and using waste to generate steam energy, and reducing the emission of air pollutants.

Wastewater reclamation through our UF/RO system removes particulates, ions, and molecules of wastewater without adding chemicals.

GRS is an international, voluntary, complete product standard developed by third parties to require verification of recycled inputs, chain of custody, social and environmental practices, and chemical regulation. GRS aims to increase the use of recycled materials in products and reduce the harmful social, environmental, and chemical impacts of production.

Sunny Special will still make efforts for sustainability and social issues to help our earth be better. It’s our responsibility to give the next generation a fantastic future.

2008

2009

2011

2015

2016

2018

2019

2020

FUTURE