In the outdoor apparel and textile industry, terms like water repellent, water resistant, and waterproof are frequently used, but they have distinct meanings. If you're getting familiar with these terms, selecting the appropriate fabric for your needs can be confusing. For instance, water-repellent jackets use a treatment to repel water droplets, while some water-resistant jackets utilize a coating to prevent water from seeping in. On the other hand, waterproof jackets employ a combination of materials to block water penetration completely. Knowing the differences and how to test for them can assist you in choosing the best water protection fabric for your purposes.

Water Repellent

What does water repellent mean?

The textile is treated with a water-repellant agent that causes water droplets to bead up and roll off the surface, making it difficult for water to penetrate. This means the fabric's surface is not water resistant only can repel contact water and dredge water droplets. Water-repellent materials are designed to resist water penetration but are not completely waterproof. Instead, they are designed to keep water from saturating the surface, causing the material to bead up and roll off, which makes water-repellent materials ideal for outdoor gear and clothing that require waterproofing while allowing for breathability.

It's important to note that water-repellent materials may lose effectiveness over time and require tumble drying after washing to maintain their water-repellent properties

Test Method

Water-repellent testing is commonly used in the textile industry to evaluate the performance of outdoor gear and clothing, such as jackets, pants, and shoes.

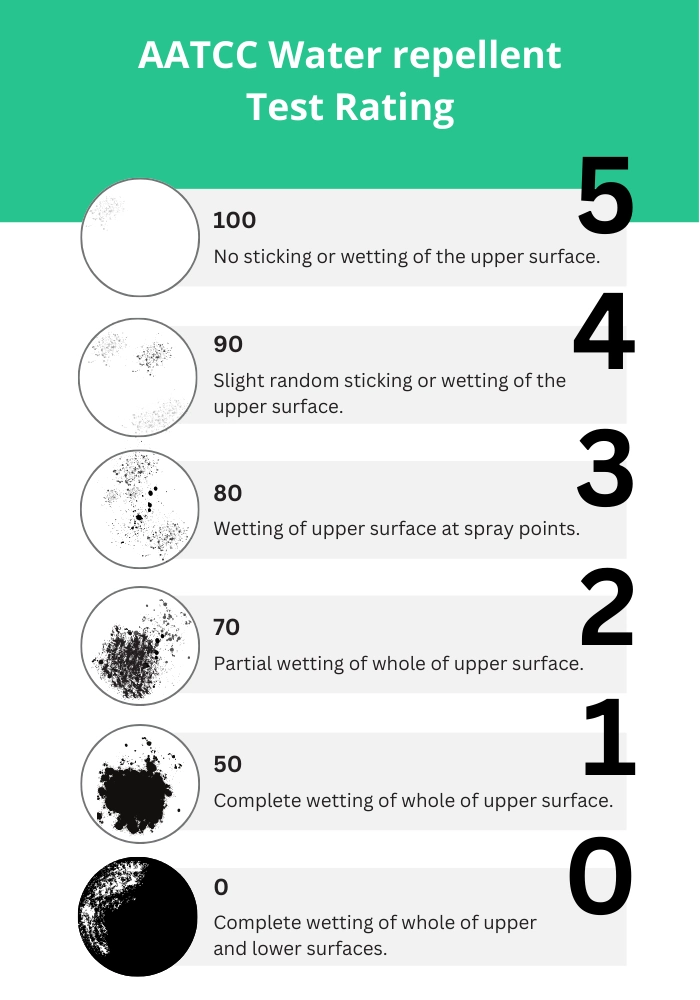

The spray test, AATCC 22, can determine the fabric's water-repellency grade. Spray the test cloth with water for a specified time, and rate the water-repellent grade according to the status of surface wetness. The less infiltration the fabric, the better the water repellency.

Rating Description:

Water Resistant

What is water resistant?

Water-resistant refers to a material or coating that can resist water penetration to some degree which means the material can withstand exposure to light rain or water splashes without becoming saturated.

How to test water resistance for jackets?

AATCC 35 water resistance is a common test method to evaluate the ability to water resistance. It stimulates the state of rain, puts the absorbing paper behind the fabric, sprays the water column pressure horizontally on the textile, and calculates the weight before and after the absorbing paper test after the specified time. The weight difference must be less than 1 gram to pass the test. Even though the water-resistant effect is not 100% the same as the waterproof material, the water-resistant fabric can resist water infiltration in quick contact and water pressure.

Here are three examples of calculating the weight difference of absorbing paper before and after the test for water resistance fabrics.

The AATCC 35 test method measures the water resistance of fabrics by determining the amount of water that passes through the material over a specified period. Here are three examples of how to calculate the weight difference of absorbing paper before and after the test:

| Sample | Test Weight (g) | Interpretation | ||

|---|---|---|---|---|

| Before | After | Difference | ||

| A | 9.10 | 15.32 | 6.22 | 6.22 g of water passed |

| B | 9.58 | 10.02 | 0.44 | Only a small amount of water passed through the fabric during the test |

| C | 8.93 | 30.22 | 21.29 | A significant amount of water passed through the fabric during the test, indicating that the fabric may not be suitable for use in wet conditions |

To calculate the weight difference, subtract the weight of the absorbing paper before the test from the weight after the test, giving you the amount of water that passed through the fabric during the test.

Waterproof

Many people wonder if water repellent means waterproof. While the two terms may seem similar, there are significant differences in their ability to resist water.

Natural waterproofing is challenging, and most textiles use the AATCC 127 water-resistant hydrostatic pressure test to measure their waterproof ability. This test applies water pressure on the fabric's front until three drops appear on the back. The higher the water pressure in the test, the better the water resistance.

A waterproof rating of 10,000 mmH₂O equals withstanding 10 meters of water pressure which is why many mountaineering and skiing clothes advertise their protection as waterproof, to provide the best possible protection against water.

How to Interpret AATCC 127 Test Results

Here are three examples of fabric results from the AATCC 127 water-resistant hydrostatic pressure test:

| Fabric | Hydrostatic Head Test Result |

Hydrostatic pressure | Recommended Use |

|---|---|---|---|

| Fabric A | 20,000 mm H₂O | Excellent | Rainwear, outdoor gear in high altitude condition, and more |

| Fabric B | 5,000 mm H₂O | Moderate | Some outdoor applications |

| Fabric C | 500 mm H₂O | Low | Urban use |

Conclusion

If we talk about which one could have long periods of protective strength, there is no doubt it will be waterproof better than the others because it usually includes water repellent and water resistance.

Following this article, you can understand the water repellent, water resistant, and waterproof, the difference, functions, and according to the test method to choose the correct fabric for your outdoor gear. To ensure your clothing provides adequate water protection, look for fabrics that have undergone proper testing and meet industry standards. With this knowledge, you can decide when to select the right water protection fabric for your needs.

You may also like