Why We Need to Redefine “Stretch”

In the outdoor and urban-performance apparel market, stretch has become a baseline expectation for woven fabrics.

From gorpcore to technical commuter-wear, brands often treat the word “stretch” as a given.

But anyone working in development knows the truth behind the label:

- Two fabrics that both say “stretch” can behave completely differently after three months of wear.

- Some lose silhouette control during pattern-making and bulk production.

- Some are difficult to process within recycling systems due to complex compositions.

- Others feel comfortable initially, but lack structural support once sewn into garments.

So the real question is no longer:

“Do you have stretch woven fabrics?”

It is:

“Where does the stretch come from, and is it the right stretch for the intended product?”

1|Where Stretch Comes From: Mechanical vs. Spandex-Based Elasticity

The origin of stretch determines comfort, lifecycle, recycling compatibility, and how well the garment maintains its intended silhouette.

Mechanical Stretch (No Elastic Fibers)

Stretch is generated through yarn engineering or weaving, rather than elastane.

Among mechanical stretch solutions, two yarn constructions dominate in woven applications:

SBS (Side-by-Side) Yarn

A bi-component polyester fiber made by combining PET (2GT) and PTT (3GT) side by side.

Because these two polymers react differently to heat and tension, they create natural crimp in the fiber—generating elastic recovery without elastane.

Pros

- Excellent recovery and shape retention

- Stable silhouette; less deformation after sewing and laundering

- More recycling-compatible due to single polymer family structure

Cons

- Lower stretch percentage than spandex

- Higher cost compared to HCR

HCR (High Crimp Recovery) Yarn

Polyester fibers are physically processed to create light crimp, giving moderate elasticity.

Pros

- Single-material composition (mono content)

- Cost-effective and sourcing-friendly

- Soft, cotton-like hand feel

Cons

- Lower elongation ability

- Less structural support for tailored silhouettes

Spandex / Elastane

The most common stretch solution in the global market, and usually the first option many design teams default to.

Pros

- High extension and comfort

- Immediate and familiar performance for consumers

Cons

- Challenging for recycling:

Low melting temperature and chemical incompatibility make separation and processing difficult in most current systems. - Limited compatibility when blended:

When mixed with multiple fibers, it may reduce the efficiency of mechanical and chemical recycling routes. - Sensitive to heat and chemicals, making process control critical in dyeing and finishing.

2|Directional Stretch: It’s Not a Spec—It’s a Strategy

2-Way Stretch

Best for:

- Commuter pants / workwear jackets

- Urban-outdoor lifestyle apparel

- Tailored silhouettes that require clean lines

Strengths:

- Shape stability and consistent appearance

- Easier to manage in manufacturing

Risk if misused:

- Restricted mobility in high-motion categories

4-Way Stretch

Best for:

- Hiking, climbing, trail, training

- Dynamic movement and performance apparel

Strengths:

- High freedom of movement and comfort

Risk if misused:

- Silhouettes may collapse; garments can appear visually “soft” or lose structure

A Simple Rule of Thumb

- If the silhouette defines the product → Start with 2-way.

- If movement is the promise → Then explore 4-way.

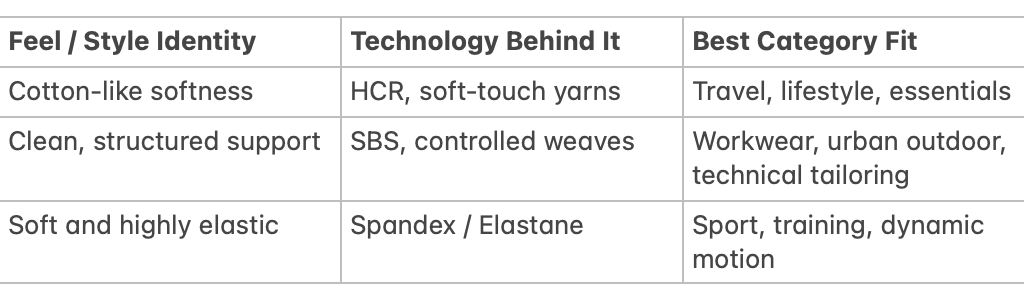

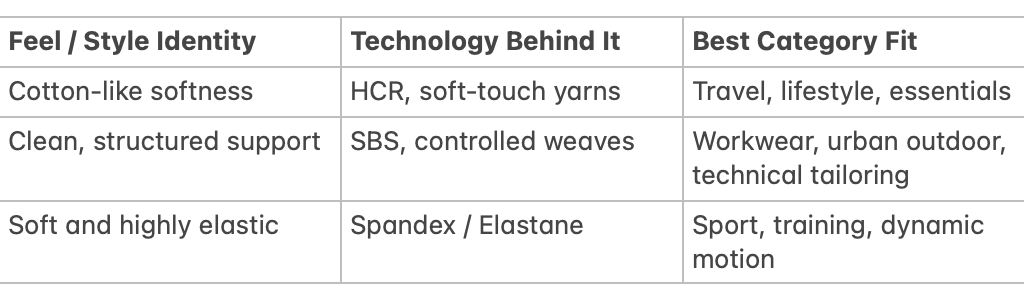

3|Hand Feel & Positioning: Stretch Isn’t the Selling Point

Stretch is a function, but how the fabric feels and behaves is what the consumer ultimately experiences.

Stretch is not the message.

Comfort, fit, silhouette, and purpose are.

Conclusion

So next time you see a fabric labeled simply as “Stretch”, ask:

- Where does the stretch come from?

Mechanical or spandex-based? - What problem was this stretch engineered to solve?

Mobility, silhouette integrity, or comfort? - Does its composition align with the product’s end-of-life pathway?

Can it be recycled, repurposed, or processed without unnecessary complexity?

Because after 2025, the question is no longer:

“Do you have stretch?”

It becomes:

“Is this the right stretch for our market, our product, and our brand direction?”

(This discussion focuses on woven fabrics. Knits are not included here.)

You may also like