In a recent interview, we spoke with James Hsu, a seasoned Program Manager at Sunny Special Dyeing & Finishing Co., Ltd. With a rich background in the chemical and textiles industry, Mr. Hsu possesses knowledge in quality management, supply chain, project coordination, and technical expertise in flame retardant (FR) fabrics and engineering plastics. Our discussion centered around the intriguing realm of high-visibility fabrics and their profound impact on workwear.

What inspired you to research high-visibility fabrics, and what is their impact on workwear?

The motivation behind developing high-visibility fabrics was to address the potential hazards associated with low visibility, aiming to improve workplace visibility and prevent accidents.

Several countries have established regulations and standards that require the use of high-visibility clothing in specific work environment. These regulations underscore the significance of visibility and advocate for adopting high-visibility fabrics to safeguard workers and ensure their safety.

The objective is to raise awareness about the technology underlying these functional fabrics and the importance of integrating high-visibility garments into the work environment. This effort aims to create safer working conditions and reduce the likelihood of accidents or injuries.

How has the demand for high-visibility fabric changed in recent years?

Workwear fabrics were primarily single-function five years ago, and high-visibility fabrics were discussed separately. During that time, the most crucial aspect of workwear fabrics was their flame-retardant performance. However, in recent times, the importance of high-visibility and flame-retardant properties has become parallel, and there has been a shift towards multi-functionality.

European and American governments and employers are now prioritizing employee safety, which increased demand for high-visibility work clothing. Developing flame-retardant fabric with high visibility, durability, breathability, and comfort is currently possible.

What is the science behind the high-visibility fabric, and what key features make it effective for workwear?

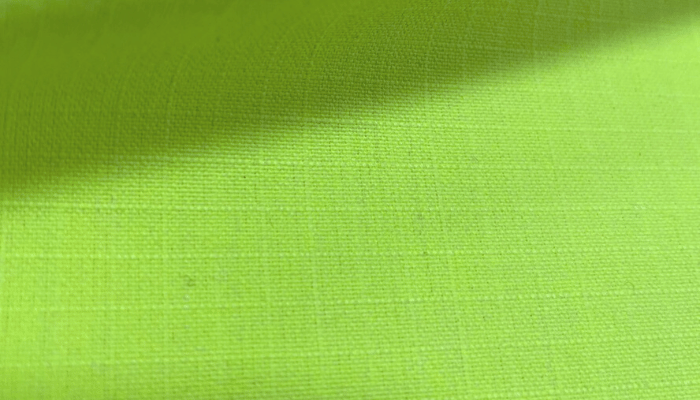

Fluorescent dyes possess high emission intensity, bright colors, and strong fluorescence. They are capable of absorbing visible light strongly and emitting fluorescence. In the case of fluorescent fabrics, when they are exposed to ultraviolet light, a portion of the ultraviolet light is reflected from the surface of the fluorescent dye, resulting in the fluorescent reflectance of the fabric. The ultraviolet light's intensity directly affects the fluorescent reflectance level. The remaining portion of the ultraviolet light is absorbed and converted by the fluorescent dye, resulting in fluorescent light emission. The absorbed energy is then converted into heat energy and dissipated.

High-visibility fabrics are designed with bright and contrasting colors like fluorescent yellow, orange, or red. These colors create a visual contrast against the surroundings, making individuals more visible in dimly lit areas.

Moreover, these fabrics are built to be durable and withstand tough work conditions. They resist fraying, tearing, and fading, ensuring they maintain functionality even after prolonged use and exposure to environmental factors such as high temperatures, humidity, and abrasion.

High-visibility fabrics adhere to specific standards and regulations to ensure consistent performance and reliability across various work environments. Combining these features, they enhance the visibility of workers, which is crucial for their safety in low-visibility or hazardous situations. Wearing high-visibility work clothing makes it easier for others to see them, reducing the risk of accidents or collisions.

Which industries or occupations rely on high-visibility workwear, and what other related functions are commonly paired with it?

The authorities advise all workers operating in a dark and unclear environment to wear high-visibility work clothing. The following are some examples that the author is familiar with:

- Oil and Gas Industry: Workers involved in drilling, refining, and pipeline operations require high-visibility, flame-resistant clothing to protect against fire and explosion risks while improving visibility in hazardous environments.

- Chemical Industry: Employees working with hazardous chemicals or in chemical processing plants need high-visibility, flame-retardant clothing to safeguard against flames, sparks, and chemical splashes while ensuring visibility for identification and safety purposes.

- Electric Utility Workers: Professionals in the electric utility sector, such as electricians and wind turbine technicians, deal with live electrical equipment and potential arc flash hazards in elevated or dimly lit locations. High-visibility, flame-retardant workwear protects against heat hazards and ensures visibility during emergencies or when working near energized equipment.

- Airports: High-visibility apparel is crucial for airport personnel to enhance visibility during taxiing, takeoff, and landing operations, especially in low light or adverse weather conditions. It enables pilots to see ground personnel, reducing the risk of accidents or collisions. Additionally, high-visibility, anti-static coveralls are important in airports where highly flammable fuels are handled, as they mitigate static electricity risks.

- Railroad Maintenance: Workers involved in railroad maintenance and repair, such as track maintainers or signaling technicians, face potential fire hazards from electrical systems or welding operations. High-visibility, flame-retardant coveralls ensure visibility and protect against potential flames and heat sources.

- Mines: Mines often have areas with poor lighting or visibility due to dust, fog, or other factors. High-visibility clothing is vital in improving visibility, allowing mine personnel to identify and locate during emergencies or evacuations quickly. This facilitates rescue operations and enhances overall safety by reducing the risk of accidents.

By incorporating high-visibility workwear, these industries prioritize the safety of their workers and minimize the chances of accidents or injuries in challenging work environment.

What are the challenges in developing and producing high-visibility, flame-retardant fabrics?

- Material limitations: The choice of materials for flame-retardant fabrics is much less than that of daily clothing. Among the limited materials, it is even more limited to be able to dye high-visibility colors. The most common flame-retardant material dyed fluorescent is acrylic force and cotton.

- Permutation and combination of material characteristics: In addition to considering factors such as tensile strength, wear resistance, durability, and comfort in the development of high-visibility flame-retardant fabrics, fire-resistant fabrics that are usually composed of multiple components must be precisely dyed. For the color in the correct color gamut, various dyes and additives must be precisely controlled in temperature, time, and pH value during the dyeing process, just like a conductor needs to control various instruments, beats, and styles to achieve a good piece of music.

In addition to technical difficulties, this kind of development takes time to try different combinations of dyeing conditions, and of course, it also requires continuous money investment to implement.

What is the future of high-visibility fabric and its use in workwear?

We have successfully developed the dyeing and finishing technology for fluorescent yellow flame-retardant fabrics. Looking ahead, we have two main goals for the next phase. Firstly, we aim to develop fluorescent orange for our fabrics further. Secondly, we plan to enhance the comfort of high-visibility, flame-retardant workwear by incorporating elasticity.

This improvement will allow the workwear to better conform to the wearer's body contours, enabling workers to perform their tasks with less restriction while maintaining visibility and ensuring safety.

Welcome to visit Sunny Special at the 2023 A+A Exhibition

Date: October 24-27, 2023

Booth no.: coming soon

Location: Dusseldorf, Germany

You may also like